Welcome to PESLL

Prospective and Early-Stage LCA Lab

PESLL research group investigates the life cycle environmental impacts of early-stage technology prior to commercialization to identify environmental hotspots and provide feedback to design of new technology.

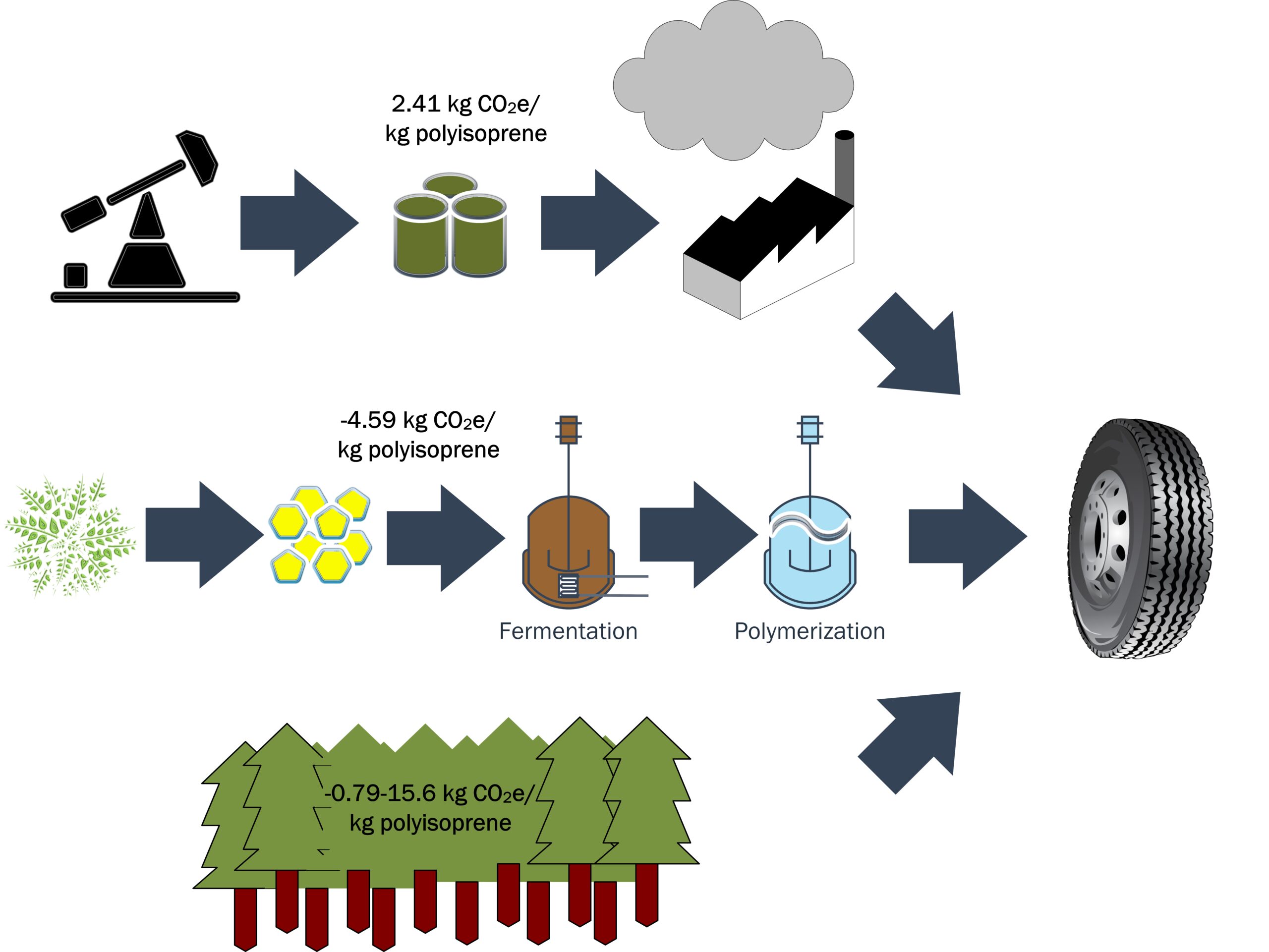

Biofuels and renewable polymers

Drawing from chemical engineering and design principles, we work on providing methodologies for generating robust and rapid life cycle inventory datasets and applying them to early-stage technology processes. This involves using early-stage technologies currently applied on a lab scale and scaling-up these technologies for the implementation on an industrial scale. The idea is to understand the implications of these technologies applied to life cycle assessment, whether it be greenhouse gas emissions, eco-toxicity, acidification potential or further environmental impacts. The work is currently a key area in addressing climate change to find alternatives for existing petroleum-sourced products, whether it be fuels or polymers. As a life cycle assessment practitioner in the polymer and fuel sector, we strive to minimize the environmental impact with regards to replacing these products to maximize the benefit for green fuels and renewable polymers.

Green Processes Evaluation

LCA informs the sustainable design and evaluation of industrial chemicals manufacture and enables computing the life cycle environmental burden of products that rely on specific chemicals. When combined with process engineering tools, it can guide the green design of early-stage chemical processes and products and evaluate the environmental tradeoffs in existing commercial chemical processes. Many chemical products are produced by batch processes, most of which use solvent-based reactions that involve energy-consuming steps to recover and then recycle only a portion of the solvents. On the other hand, new technologies emerge to replace old technologies which cause an environmental burden. Thus, combining the benefits of green chemistry and specifically solvent elimination, our objective is to test the environmental and economic performance of mechanochemistry syntheses by LCA evaluation.

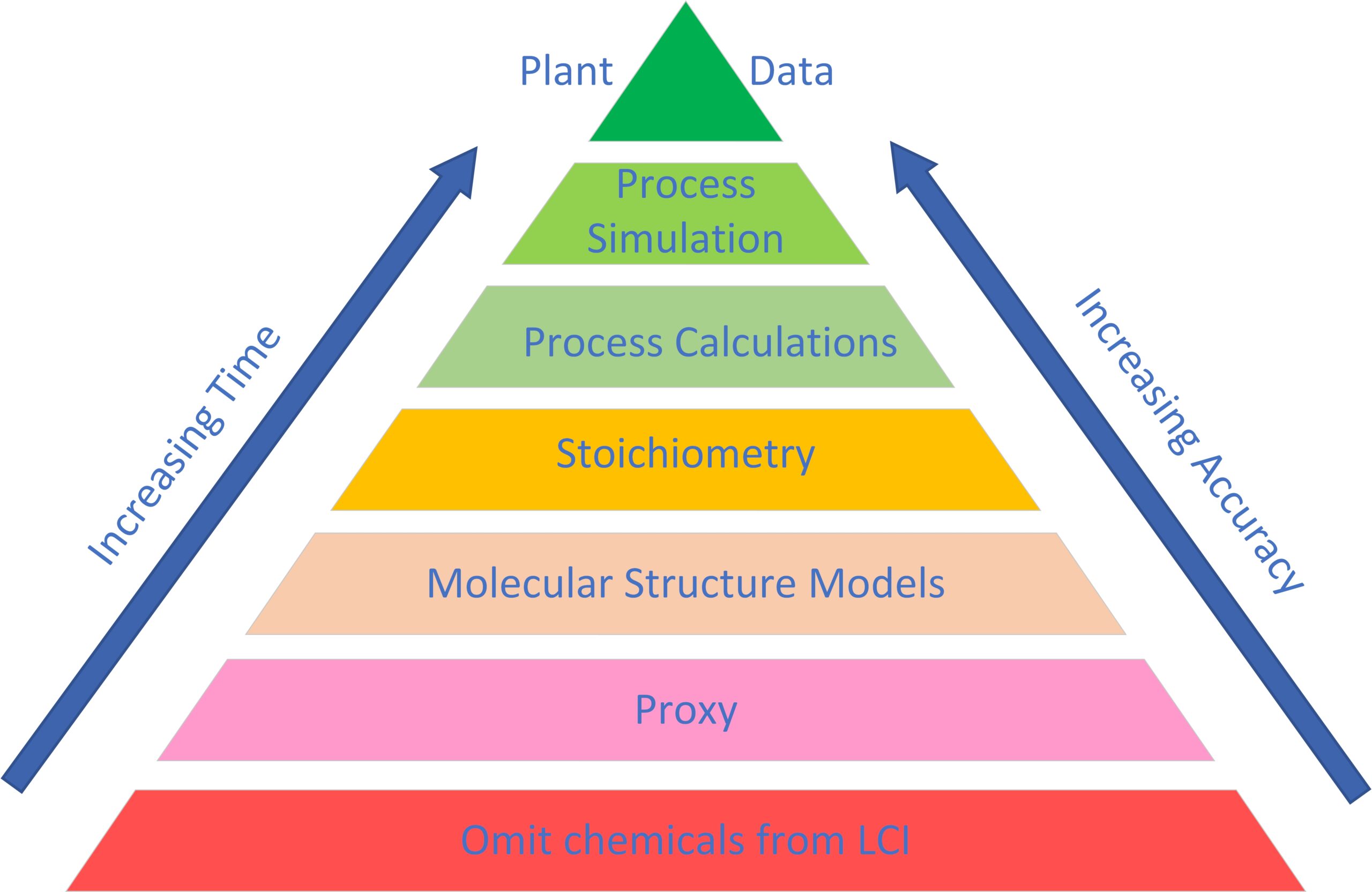

Data Prediction for Life cycle inventory

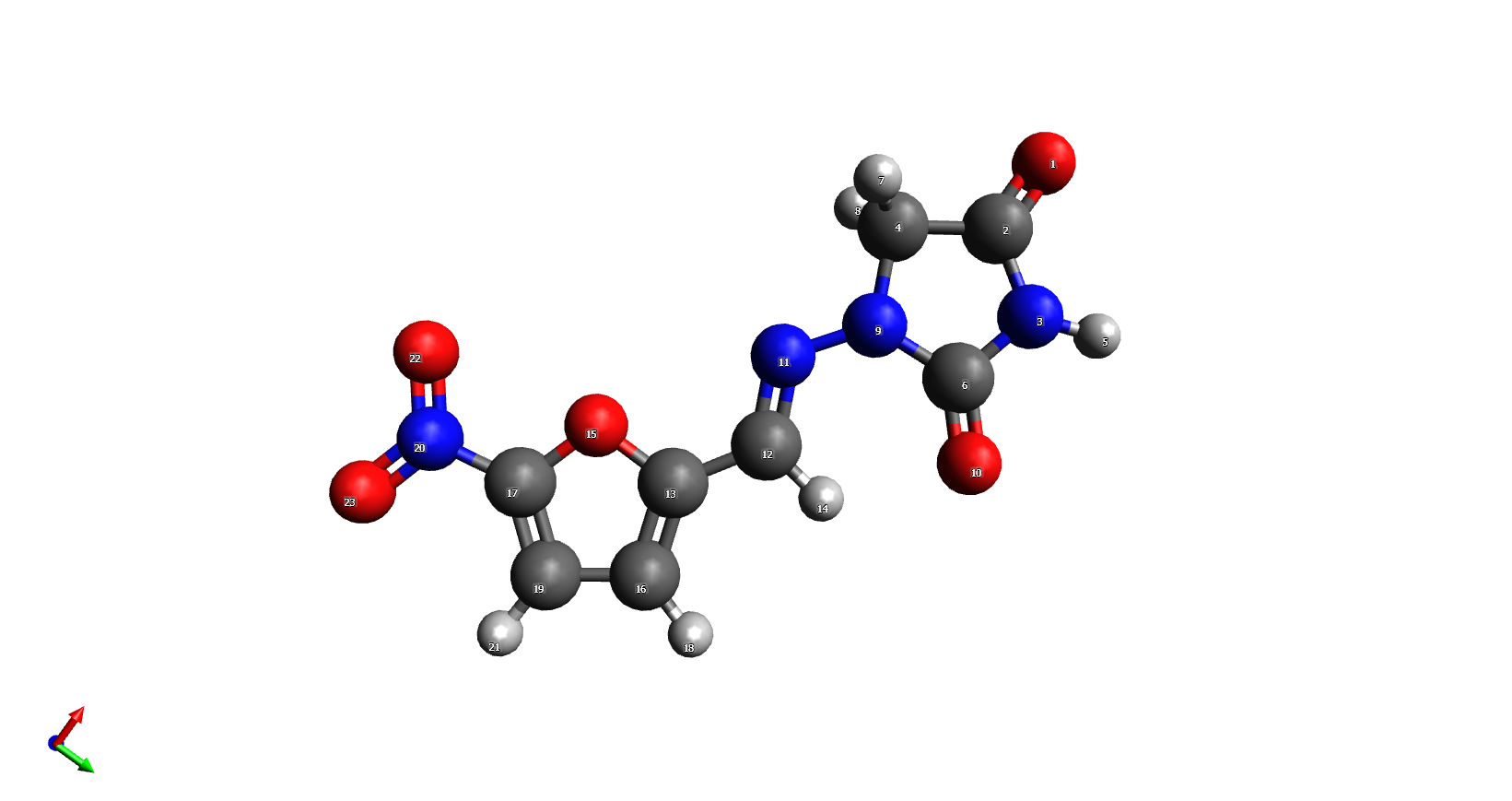

Life cycle environmental impacts can be challenging due to the absence of data needed to characterize reaction chemistry, which is the basis of material and energy balances that comprise the life cycle inventory (LCI). Our approach involves the usage of multi-scale molecular modelling, particularly molecular dynamics (MD) at the atomic level, in combination with process simulation design, to fill gaps in data for the generation of LCIs of early-stage materials and production processes. Within this area, system force fields of low technology ready materials can provide descriptions on the atomic level using systems such as OPLS for parameterization for energetics, along with bond and angle parameters. MD simulations are built with varying conditions, depending on the desired thermodynamic properties. Computational software, e.g. LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator), is used to perform the MD simulations. The development of this method will enable evaluating the performance of new chemical processes more streamline in terms of its environmental impacts and by that, will encourage both academia and industry to invest in new developed synthesis routes based on known and quantified LCA results.